Gavilon Fertilizer Partners With Marcus Construction to Renovate Facility

What They Needed

Gavilon Fertilizer in Port of Catoosa, OK, was at a crossroads. The roof and floor of its warehouse were still in good condition. However, the interior rodded bin walls and outer front wall were deteriorating. The portions of the walls that were deteriorating increased facility repair costs, product shrink, labor, and demurrage. It seemed a shame to demolish the whole facility and start new, yet the leaders at Gavilon knew something needed to be done to update their Port of Catoosa terminal. Operationally, Gavilon was concerned about building new and needing to temporarily close for business.

Gavilon brought in Marcus Construction. After exploring different options, both parties agreed on the value of the existing roof/floor and decided a renovation would be the most cost-effective solution.

What We Designed

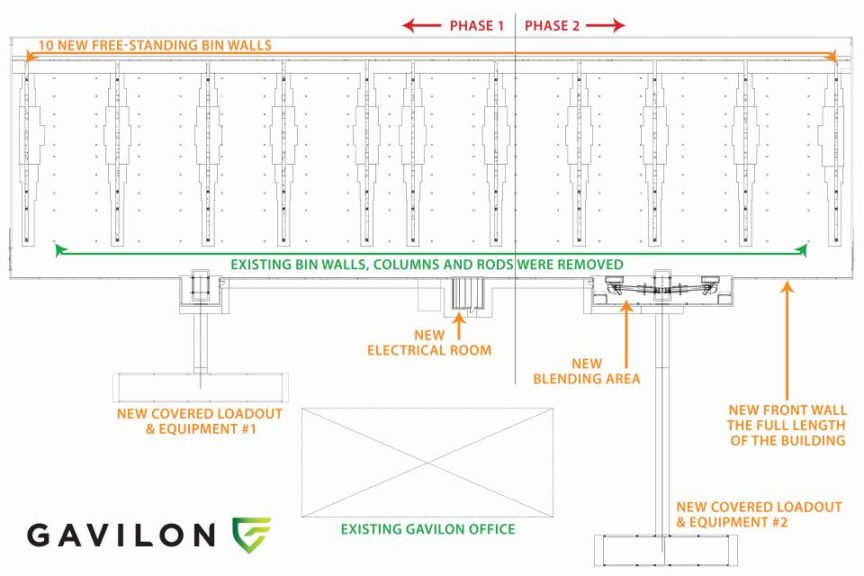

By choosing a remodel instead of a rebuild, Gavilon wanted to continue unloading barges into its limited storage space and loading out products into trucks/railcars. With this in mind, safety was a priority, knowing both Marcus’ construction traffic and Gavilon’s fall fertilizer season traffic would be active inside the warehouse. The solution was a two-phase approach. This gave Gavilon and Marcus access to different ends of the building — allowing operations to continue alongside the remodel.

Marcus Construction demolished the 12 existing bin walls while keeping the roof supports and overhead conveyor in operation. Marcus designed and constructed new free-standing bin walls to stack product full height without the need for braces, rods, or unwanted columns — making it an open and safe space that supports the roof and conveyor system. The new bin design added an additional 14,000 tons of storage, taking Gavilon’s storage capacity from 29,000 to 43,000 tons on the same footprint.

The decision to rebuild solved Gavilon’s problems — it was able to salvage valuable parts of its existing structure at significant cost savings along with being able to continue servicing its customers throughout construction.