Fertilizer Blending: Embracing Technology Through Automation

As the president of Doyle Equipment Manufacturing, Monty Doyle has visited retail fertilizer locations across the country. In the process, he never passes judgment as to what his clients might or might not know about blending software.

“Adoption is an issue that can’t be assumed,” Doyle says. “My observation is that there is a lot of new software and technology coming down the pipeline. The plant managers and operators of these locations have a big job already, and for them to take the time to learn and adopt these new technologies is a challenge.”

The end goal, Doyle adds, is that new technology and software should always bring efficiency to the end user.

How do retail plant managers and operators achieve that aim? What are some industry issues that they might not realize but should? Seven blending software authorities offer their insight:

• AGI Fertilizer Systems — Automation and blending software have been an afterthought to fertilizer blending facilities, according to Territory Sales Manager Shane Rollins. “Blending and automation software should be part of your early discussion,” he says. “Whether you’re building a new state-of-the-art facility or upgrading an older plant, adopting and embracing technology will allow you to stay profitable through the coming years.”

• AgWorks — As companies transition to automatic blenders, it becomes critical for operational software to interface with those blenders for maximum efficiency, according to Director of Sales Matt Hull. “All application data is valuable when analyzing what happened over the course of a season to see how different treatments impacted yield,” he says. “Being able to quickly create a work order, send that information to a blender, and then dispatch that order in a matter of seconds saves time so that more work can be done. It creates huge efficiencies, which can lead to less manpower needed to run everything.”

• Doyle Equipment Manufacturing — Retail plant operators and managers need to realize there is a wide spectrum to blending software, according to Monty Doyle. “A blend system that only turns on, blends a load of fertilizer, and loads the blend on a truck or in an overhead tank is not a fully automated/integrated system,” he says. “Systems that only do one part of the process and require a person’s time entering orders into the blend system or typing orders into an accounting program are not fully automated. In some cases, this is what Doyle would refer to as manual operation.”

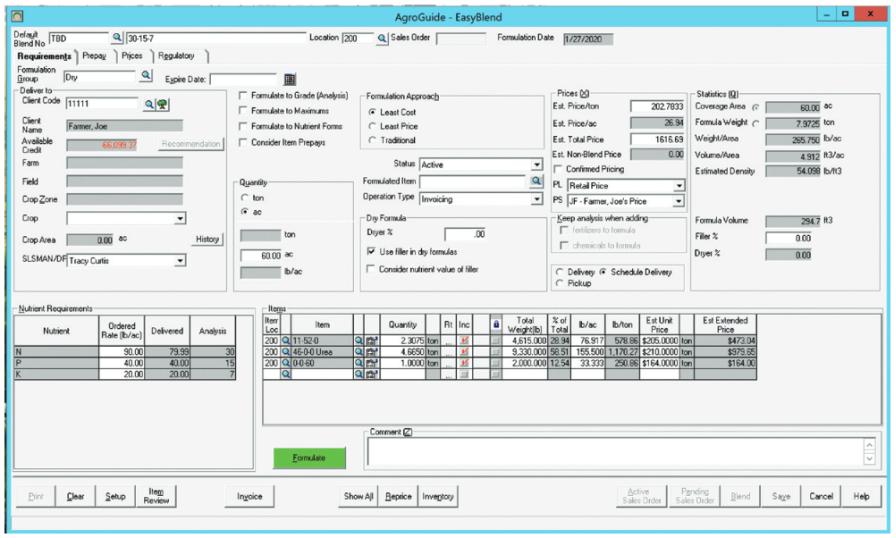

The screenshot illustrates the capabilities of AgroGuide, the fertilizer blending capability within AGRIS, one of Greenstone’s core systems. Photo courtesy: Greenstone Systems

• Greenstone Systems — The ability to execute work orders that include blends quickly and efficiently and then invoice those orders accurately and timely are most pressing to users, according to Head of Product Mike Terning. “Satisfying growers with accurate information that proves accurate execution of the orders is vitally important,” he says. “There is an increasing desire of growers to have a transparent view into the status of their orders, including a history of what has been done.”

• Kahler Automation — System automation provided by blending software offers the potential of a complete site-wide solution with long-term benefits, according to Vice President of Sales Mark Mohr.

In addition to greater plant output, facility automation can improve invoice accuracy, increase workplace safety, ensure consistency, and maximize office productivity, he says. “Many managers also find new ways of using the real-time inventory from the automation software. With a more complete and real-time view of inventory based on blending and dispensing, rather than a delayed view based on invoicing, this is a great tool for more efficient inventory management and improved customer service,” Mohr says.

• Murray Equipment — Blending software is intuitive now, Sales and Marketing Director Todd Scobie says. Comments he typically hears from clients include: “I was concerned about having to learn new software, but it’s so easy!” “It’s way better than what we did before!” “The system is so fast, and our customers are extremely pleased.” This, Scobie adds, “is what we hear all the time from plant managers.”

• Sackett-Waconia — The “single-most” pressing issue, according to Director of Business Development Charles Formisani, is speed. And a “very close second,” he adds, is the ability to incorporate new value-added products. “Speed is driven by the challenging logistics of moving fertilizer while achieving the 4Rs in the field,” Formisani says. “This also, in many ways, leads to the use of more value-added products, which is why we see these two major issues/challenges very much coinciding.”

Bottom Lines

According to Formisani, the continued need for upgraded blending systems is being driven by the continued shrinking windows for application, which leads to requiring higher speeds, and also more development in the value-added and enhanced-efficiency fertilizer market. As a result, there is a need for more flexibility and precision from the blending systems.

“The challenge currently is with a flat ag market and limited capital to make these upgrades,” Formisani says. “We are seeing several projects where the blending system and bulk fertilizer building may be upgraded in phases instead of all at once. We are forecasting the continuation of requiring both faster, more accurate blending systems and higher flexibility in them. As environmental pressures increase, higher nutrient-use efficiency requirements will mean development of more technology in value-added products. The key will be in designing blending systems to have the flexibility to add these products both efficiently and quickly.”

Increasing return on investment (ROI) or return on assets (ROA) is driving the industry, Mohr says, whether a retailer is building new or managing an existing facility, typically with a small staff. “Nearly every manager is experiencing the push to get more margin-generating product through a facility accurately, with a small number of skilled plant and office staff,” Mohr says. “In this environment, significant gains are made by partnering with a systems control and software provider that approaches blending as a system rather than a task.”

With this approach, the best solutions automatically manage the data in addition to the blending, Mohr says, so orders are received from agronomy and accounting systems, accurately blended and dispensed, and actuals are reported to the accounting program for invoicing. “This higher level of system automation increases your entire facility’s performance and offers financial gains through productivity and accuracy in the plant and in the office,” he says.

Automating the majority of a fertilizer plant’s operations allows skilled employees to scale their abilities and efforts, Rollins says. “Allowing skilled employees to do more for your organization aids in an efficient customer experience,” he says. “Through strategic partnerships with ERP (enterprise resource planning) accounting and agronomy platforms, we are automating tasks, such as receiving and blending product while creating a single point of data entry for reduced human error. Automated systems lead to higher productivity, happier employees, and satisfied customers.”

Finally, Doyle suggests a little common sense goes a long way. “People are not taking the time to learn what they have available to them at their fingertips,” he says. “Learn your software and utilize what you have to get the most efficiency from your system.”

Company News

• AGI Fertilizer Systems — The company last year decided to apply the same dedication and excellence toward software and automation that it had while providing state-of-the-art fertilizer equipment, Rollins says. By combining Yargus and Junge Controls software platforms into one consolidated solution, “we are steadily working to provide our customers with simple, dependable software for liquid and dry fertilizer facilities,” he says.

• AgWorks — The company’s data analytics platform, HighQ, continues to adapt and move forward to meet industry needs, Hull says. This year AgWorks is partnering with FieldReveal, which allows the company to take variable-rate prescriptions, zone information, soil sample data, and nutrients applied and perform a deeper analysis of a field, Hull says. “There is a large amount of data that is captured from the start to end of a season, and HighQ allows retailers to prove the performance of different treatments,” he says.

• Doyle Equipment Manufacturing — The company last year introduced the industry’s first 24-ton rotary blender, which, according to Monty Doyle, is a “game changer” in terms of getting semi-load quantities of quality fertilizer blends loaded quickly in a single batch.

• Greenstone Systems — AgroGuide, the fertilizer blending capability within the company’s AGRIS core system, makes it “much easier” to audit and analyze blend history, Terning says. In addition, the company’s Sale App makes it “easier, faster, and more accurate” for sales agronomists to capture deals with growers anywhere via mobile device. “This includes quoting prices to farmers and then turning those quotes into booking and/or prepays,” he says.

• Kahler Automation — Strategic partnerships are becoming increasingly important as managers and customers expect more of existing facilities and highly efficient new ones, Mohr says. “These can range from facilities with a few products that need an effective solution today that’s poised for future growth, to complex facilities with numerous product types and owners,” he says. Kahler’s software and support services subscriptions are welcomed by managers and operators of any size facility while providing the right tools to operate at peak performance when it’s “time to go,” Mohr says.

• Murray Equipment — The company continues to add to its blending software, ICS ControlPro, new features that address the increasingly complex business models of ag retailers, wholesalers, and manufacturers, Scobie says. “The direction and development of ICS ControlPro is intricately tied to actual challenges faced by Murray Equipment customers, which span the entire industry,” he says. “Improved resource management and more executive summary tools are currently being developed and deployed.”

• Sackett-Waconia — “Last year saw a continued transition from bigger to be faster, which sometimes means giving up quality for speed, to where we are heading, which is achieving speed, precision, quality, and flexibility without sacrificing any one of these,” Formisani says. This year will feature continued development in the company’s blending technology, combined with a more integrated approach with automation and specialty systems for the incorporation of value-added products. “No two locations are alike, so we will continue to focus on custom designs to meet the needs of each location,” Formisani says. “Of course, safety and worker environment are always in continuous improvement, with more stair access, reduced dust and spillage, etc.”