Dicamba Update: Herbicide Application Expert Shares ‘Drift Big 4’

A slide from University of Nebraska-Lincoln’s Dr. Greg Kruger’s presentation on the “Drift Big 4” from January’s Precision University event, hosted by The Ohio State University, in London, OH.

“A farm kid with a license to conduct research.”

If you’ve never witnessed him speak at an event, this is how University of Nebraska-Lincoln Extension researcher and wind-tunnel steward Dr. Greg Kruger self-describes.

Now, being a self-described sports nut myself, anytime someone references a Big 3 or a Big 4, or even a Fab Five (that was the University of Michigan’s revolutionary all-freshman basketball lineup for all the Millennials in the house!), my already-too-big-for-my-head ears tend to perk up.

Attending The Ohio State University’s annual Precision University seminar back in January, one of the speakers on the docket was the aforementioned University of Nebraska’s Kruger, who talked about some of the challenges with dicamba application in the past and some insights he’s gained over the years conducting research both in the wind tunnel at UNL, as well as in the field.

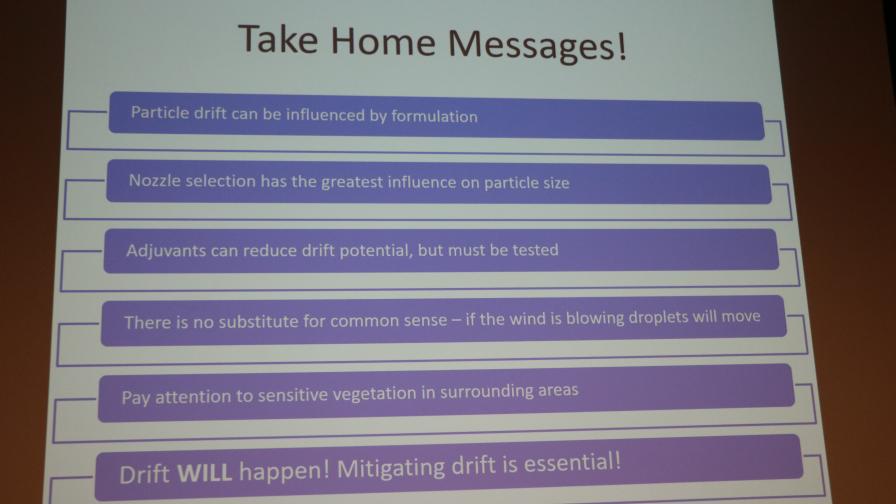

A subject Kruger likes to refer to as his “Drift Big 4,” which it should be noted is not exclusive to the dicamba molecule, rather they are best practices that can be applied to the application of virtually any pesticide, herbicide, fungicide, etc. Here are Dr. Kruger’s Drift Big 4:

- Wind Speed: According to research conducted in the wind-tunnel, Kruger shared that when wind speed in the field doubles drift occurrences have the potential to increase some 700% when readings are taken 90 feet from the boom. “Hence,” Kruger shared, “it’s why the label specifies spraying when wind speeds are under 10 mph.”

- Boom Height: Again, Kruger and team have found that an increase in boom height from 18” above the crop canopy to 36” results in a 350% increase in drift occurrences. Today’s dicamba label sets boom height restrictions at 24” from the plant canopy, so making sure the boom stays between the 18”-24” window is a good way to manage drift.

- Distance from Susceptible Vegetation: Kruger and his team have found that increasing the size of the saturated buffer strip between a dicamba-tolerant and an adjacent non-DT crop field from 50 feet wide to 100 feet results in an 80% decrease in particle drift.

- Spray Particle Size: Kruger says that one of the most important aspects of application science applicators should keep in mind is the fact that droplet size is directly correlated to spray efficacy. Generally speaking, the coarser, or fatter, the droplet size when applying dicamba, the less effective (i.e., less weed control) the product will be in the field. This aspect of application is also effected by adjuvants in the tank mix, as Kruger recently told Jackie Pucci that pushing a 650-micron drop up into the 750-800 micron range by adding a drift reduction agent (DRA) will have a negative effect on product coverage and efficacy.

Kruger’s “Drift Big 4” presentation takeaways slide.

Get top-of-mind reminders on the latest compliance and regulatory rules on dicamba, as well as insight from industry experts, directly to your email inbox. Subscribe to CropLife’s Dicamba Update.