4 Not-So-Obvious Strategies for Stopping Dicamba Drift

Editor’s note: CropLife Senior Writer Jackie Pucci has been covering dicamba technologies — and the issues and challenges related to them — for the past two-plus years. In that time, she has gained valuable insight by interviewing dozens of experts on this critical topic. Here she offers four not-so-obvious strategies to consider when managing dicamba spray drift.

1. Don’t Just Check Boxes, and Make Every Drop Count

More so now than ever before, we’re in a balancing act with dicamba, says Jim Reiss, Vice President of Product Development for Precision Laboratories.

Jim Reiss

“We’re in this business of making big droplets to minimize off-target movement. We can end up with great drift control but not good control of weeds,” says Reiss, who also serves as current Chairman of the Board of the Council of Producers & Distributors of Agrotechnology.

Further, Reiss cautions that, by mixing and matching any approved adjuvant with any nozzle inside of Bayer’s corresponding “red box” lists, “you have met EPA’s criteria, but the most important criteria — which is why you’re out there to spray — is to kill weeds first. Just because I have a nozzle and chosen an adjuvant, I’m not on my way to nirvana yet.”

We asked Reiss why optimal adjuvant-nozzle combinations are not spelled out on the label. “Possibly nobody else is looking at it. But we have,” he says. “It’s not something we’ve chosen to put on the label, but we speak about it with customers. We make presentations. We show them better options.”

Gary Schmitz, BASF Technical Services Regional Manager, notes that in most cases, applicators just need to make sure they have the right pressure. “Generally, in some of the ultra-coarse-producing spray nozzles, they need to keep a minimum of 40 psi. If they drop down below that, they start to lose coverage,” he says.

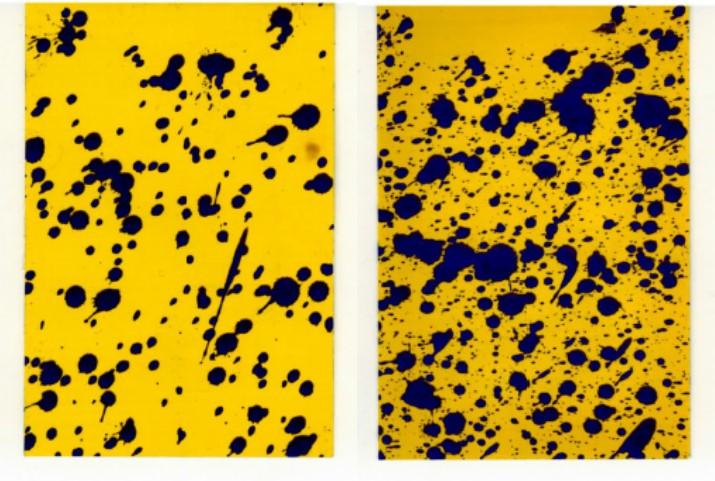

The spray card on the left is mixed with Astonish; the card on the right is mixed with Intact Advanced and shows a 64% improvement in coverage.

Precision Labs also sought a solution beyond creating mega-sized droplets that can result in poor coverage and eventual resistance issues. The company uses organic polymer technology to enhance the behavior of the droplet so that it sticks to the leaf.

“A lot of people refer to it as sticking, but droplet retention is what we need to think about,” Reiss says, noting that his company’s guar-based Intact drift reduction agent is geared toward doing exactly this. Intact was the first drift-reduction agent (DRA) red-boxed on Bayer’s tank-mix products list, while Intact Advanced adds a water-conditioning agent in conjunction with the DRA and foliar retention elements. While either of these products works well with a wider range of approved nozzles, a couple of nozzles that have shown more consistent performance in both area and distribution of droplet coverage include the Turbo TeeJet Induction (TTI) and Ultra Lo-Drift (ULD), he adds.

2. Consider Hoods

If Steve Claussen had it his way, U.S. EPA would amend the dicamba label today to allow for spraying in higher wind speeds than the 3-to-10 mph range currently permitted — so long as a spray hood is used.

Redball SPK645 self-propelled broadcast retrofit hood kit in use in an Illinois soybean field. Photo courtesy of Steve Claussen

A hood, you say? “We try to keep chemical where it’s intended to be sprayed, in a simple and inexpensive way that just about anybody can understand. If you put a spray tip in an enclosure and spray, you’re eliminating wind and other things that can happen from Mother Nature,” says Claussen, Founder and President of Willmar Fabrication, maker of Redball sprayer hoods.

Down in southern cotton fields, they’re a common sight, but up North, spray hoods remain somewhat of a mystery to many growers.

Hoods take only about 10 minutes to put on and off, he says — but time is money. More to the point, there is no legal way in which to use hoods to see the clear benefits of reduced drift and improved deposition, as an applicator still has to abide by buffers and can’t spray if winds are stronger than 10 mph. In Canada and Europe, Claussen says, credit is given to applicators that use hoods or shields in the way of a 70% to 100% reduction in buffers, depending on the chemistry.

Claussen grew up on a Minnesota farm, not far from where he and his brother invented the Redball Monitor in 1983 for monitoring fertilizer. Soon after, they developed the Redball spray hood for pre-Roundup Ready cotton growers to fight weeds between rows. “Everybody in the South knows about Redball hoods, but up North, we never had the need or awareness or any company to help us push it.”

Ahead of the release of dicamba-resistant technologies, Claussen sensed opportunity, knowing what he did about the molecule’s propensity to drift. He redesigned the company’s original hood with a goal of 100% drift reduction.

“I wanted to get where we could control all drift with the hood in all conditions. I’m not saying it does that, but it does it much more effectively than anything else on the market, from a consistency, day-in-and-day-out point of view,” he says.

In 2013 he took the hoods to Dr. Greg Kruger at University of Nebraska and Dr. Dan Reynolds at Mississippi State University, who undertook three years of studies using glyphosate, which yielded two papers, one published in 2014 and the other in 2018. The studies demonstrated that hooded sprayers “considerably reduced drift of all tested spray qualities at short distances downwind, including up to 86% less with a fine spray quality.

Additionally, at longer distances up to 300 feet downwind, both larger spray qualities and sprayer hoods reduced drift independently.”

He took the data to EPA, but that’s not all. He also dragged a sprayer boom, complete with hoods, along with him on the road to Maryland, just outside of DC, to show the agency its powers up close and in person. “Fifteen EPA staff and managers came, and we got their attention for four hours,” he says.

EPA encouraged him to seek the support of the dicamba or other pesticide registrants, at least one of which would need to make the request to change the label to allow applications with reduced buffers or higher wind speeds.

“We’re still trying to find the registrant or someone that wants to team up and jointly promote what the hoods can do, just like we did in the South,” Claussen says. “Right now, it’s awareness as much as anything. With the awareness will come label changes, just like in Canada and Europe. It’s just a matter of where and when.”

3. Boost Productivity with Minor Tweaks

If only complying with the dicamba label were as mindless and carefree as lying on a beach somewhere with a tropical drink in hand. Instead, there’s a good chance you’ll have fewer hours to apply it legally over the spray season than you are years old. And if you’re rushing through an application process out of fear conditions will go south, you’re more likely to make missteps that could potentially cause you to drift onto a neighboring farm.

Dr. Tom Wolf, partner at Sprayers101.com (Twitter: @nozzle_guy), resides in Saskatchewan, Canada, where dicamba-resistant technologies are used sparingly in comparison to the U.S. but are used nonetheless. A consultant to retailers and applicators across Canada and scientist specializing in low-drift application methods, Wolf advocates several approaches to consider:

• Slow down and save time. Driving at slower speeds allows the applicator to lower the boom, creating less turbulent air that might pull droplets up higher and predispose them to drift. “It’s just good practice,” he acknowledges. “Obviously, when you drive slower, you lose productivity. We are focusing on finding that productivity again.”

To do that, Wolf advises people to fill faster and better manage non-spraying time to minimize down time. Trading out a 2-inch pump for a 3-inch pump can cut the fill time of an average spray tank down to five minutes from the typical 20 to 30 minutes.

He also encourages the use of induction, using a venturi, which can suck the material into the tank much faster.

• Evaluate the situation daily. Wolf asks customers to not make blanket assumptions to spraying: “‘This is how fast I’m going to drive, and this is how much water I’m going to use,’ but rather to evaluate each single day and say, ‘OK, today I only have to spray a 200-acre field. This is how fast I’m going to drive, and the forecast is decent. Therefore, I have time to be cautious and to take extra care,’” he says. “Another day, you might need to spray 1,000 acres, and the weather might not be as good. On that day being productive is also important. It might not let you spray slower, but at least it will let you get the job done when the weather is still good. That all comes in together in the quality of the spray job.”

Wolf adds: “We are on the same wavelength with our American counterparts — this is not a Canadian idea. We are trying to convert as many people as possible who aren’t there yet.”

4. Use Inversion Monitoring Tools

Preventing drift comes down to planning and, of course, following the label, reminds BASF’s Schmitz, who points users to engeniastewardship.com to access detailed checklists and a spray tool to pinpoint ideal spraying times and days for your exact location.

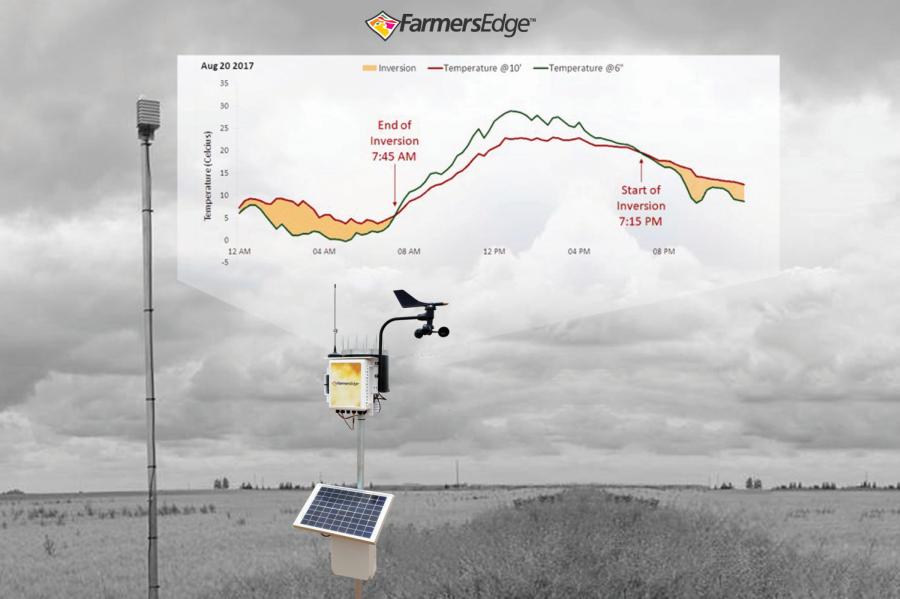

Precision tools can come in handy, too. Farmers Edge, for example, has a Delta-T indicator tied to every single one of its 4,500 weather stations in North America. A grower opens their Farmers Edge weather app, clicks on the weather station closest to their field, and in an instant a score of 1-10 is displayed signaling whether it’s acceptable to spray at any given moment.

Farmers Edge has also installed a Regional Inversion Monitoring Network, offering a true, physical indication of actual temperatures at ground level compared to the above-the-crop canopy, says Jamie Denbow, Global Digital Ag Lead. The network consists of 20 inversion towers, and it’s constantly adding to that number. “We want to do whatever we can to assist growers to make the right decisions. The more weather stations that we install, as growers partner with Farmers Edge, the more granularity it creates in the monitoring system,” Denbow says, adding that the company is at work on a system that will push out notifications to an applicator when conditions to spray are right.