Kahler Automation Helps CHS Dakota Ag Cooperative Build For The Future

CHS Dakota Ag Cooperative in Mooreton, ND, wanted a liquid/dry blender system that could meet the needs of its customers today and in the future. And Kahler Automation helped them build it.

What They Needed

Doug Kuruc, Agronomy Manager at CHS Dakota Ag Cooperative, said that working with EJ Beek and Kahler Automation on several smaller scale projects and having used Kahler in other dry plants, the company knew what Kahler was capable of. “We knew Kahler Automation had the knowledge and we knew their track record,” said Kuruc. “We didn’t spend money to build this facility, we invested money to build this facility.”

“Liquid fertilizer is an important part of crop production, especially corn,” Kuruc added. “It’s part of the package for high yields. We manufacture our own blends, custom to the growers.”

What We Designed

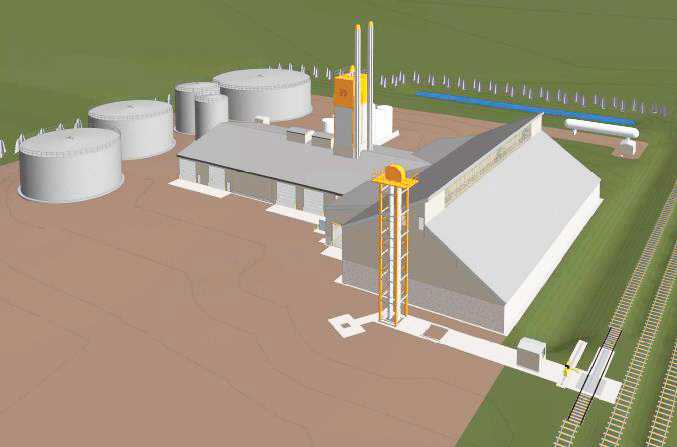

The liquid/dry blender system can load a tanker truck in 3½ minutes. This system has the ability to custom blend directly for loadout and also manufacture blends into storage. Customers come from all parts of North Dakota, South Dakota and Minneapolis for this service. The elevated manifolds and meters in the Dakota Ag design saved on floor space and additional piping.

Three million-gallon liquid fertilizer storage with two loadout bays and 15,000 ton dry plant storage with two loadout bays, fully automated by Kahler, keep things moving. “We don’t have 8 a.m. to 5 p.m. customers anymore. With 24/7 unstaffed controls, the drivers don’t even come into the office,” said Kuruc.