AGI Fertilizer Systems Provides High-Speed Fertilizer Loadout for Nutrien Ag Solutions

AGI Fertilizer Systems unifies Junge Control and Yargus Manufacturing while adding the strength and diversity of the products of AGI. Together, AGI Fertilizer Systems is the leading provider of equipment for both dry and liquid fertilizer material handling. That, paired with our own in-house automation programming and control systems, makes AGI Fertilizer Systems an easy choice for your turnkey fertilizer plant solutions.

AGI Fertilizer Systems was tasked with providing a state-of-the-art facility for Nutrien Ag Solutions in Galva, IL. We were expected to meet minimum loadout times, automated control system functions, and safe working environment needs, which were all met.

What They Needed

Nutrien wanted to improve its market share by adding a green field location in Galva, IL. AGI Yargus and Junge worked with a Nutrien team that included the regional manager and construction management department to lay out the best design for dry fertilizer and liquid handling solutions.

What We Designed

Dry fertilizer handling solution:

We designed the equipment to perform at the most efficient speed for maximizing performance. The receiving system is rated at 200 TPH, allowing a semi-truck to unload in 10 minutes while the DW system is rated at 300 TPH and can load a truck in five to 10 minutes. Nutrien chose the DW system on the loadout equipment based on its speed. The DW system includes the automation package in the blend system, a benefit of partnering with AGI Yargus. We interface directly with the Nutrien ARS program to allow tickets to self-populate in our program to eliminate human error. Nutrien also has the capabilities to see how much product has run through each hopper to track inventory on a daily, weekly, monthly, or yearly basis. The AGI Yargus solution met Nutrien’s need for speed while providing world-class inventory tracking.

Liquid fertilizer handling solution:

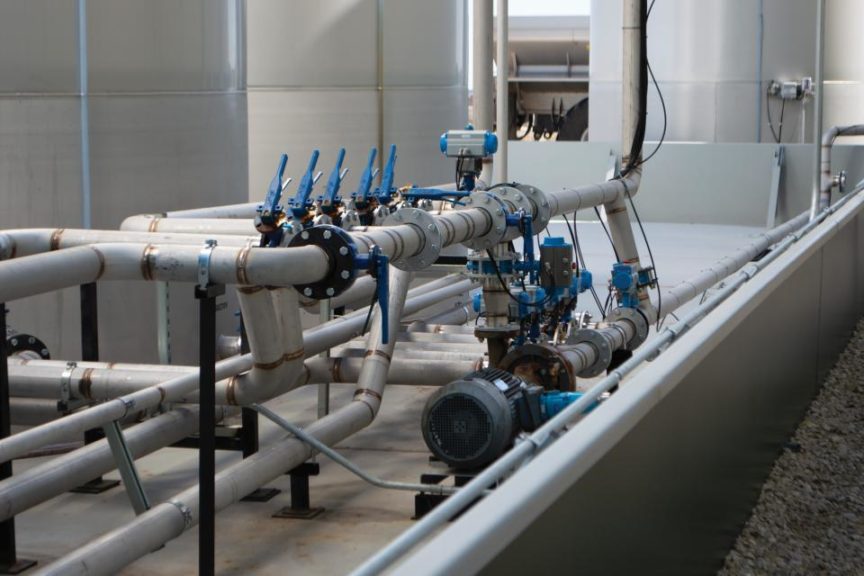

Fertilizers and water are handled through a NTEP-certified mass meter system. Nutrien’s Black Label product is segregated to a separate loadout line to avoid the staining of pipes and discoloration of other “clear” products. An AGI-Junge Control 250-gallon NTEP-certified weigh system is used to handle bulk chemicals. Micronutrient and chemical shuttles, including rinse aid tanks, are injected into the loadout lines using a Venturi bypass system. An automated pallet loading system is put on an NTEP-certified pallet scale and connected to the software system.

These systems are controlled by AGI-Junge Control’s fully automated control panels and software, which maintains all information from all systems to the software database, deals with actuals, and automatically adjusts free falls, and can integrate with blending and billing programs. The data base monitors inventory usage by day, product, and customer, with information on more than 100 possible data points for each product/load used.