Ag Equipment: What Does Sprayer Productivity Cost?

Size is usually a major factor when purchasing a new sprayer. Larger sprayers tend to be more productive, and a balance must be found between the sprayer investment and the amount of work to be done. Recently some interesting conclusions and numbers were uncovered during research conducted for a new study.

It is difficult to evaluate machinery costs and return on investment (ROI). In this case field efficiencies, sprayer sizes, and prices were evaluated. One of the tools used was a sprayer productivity calculator published by Tom Wolf and Jason Deveau of Sprayers101.com.

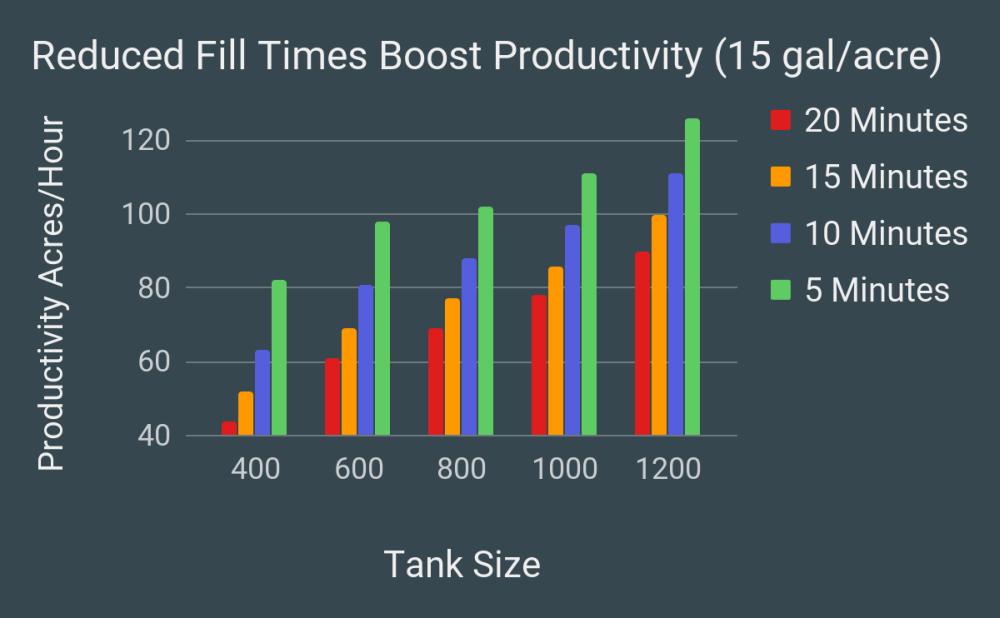

The calculator was used to compare various sizes of sprayers and evaluate the options as objectively as possible. The smaller sprayers did get a slightly higher turn-speed in the calculations since they are of lighter weight and usually more agile. The factors used in the calculations were half-mile field length, two headlands, 15 gallons per acre, and 14 mph spraying speed. Boom width, tank size, ground speed, and loading time options were also compared. Looking at all of these, faster loading times provided the best productivity improvement by a significant margin.

Pricing Comparisons

Two brands of sprayers were priced from local dealers, and the prices were averaged together for the comparisons. The sprayers were equipped with the latest pulsing-nozzle technology and auto-guidance systems. The smaller sprayers did not have quite as many features since some of the options were only available on the larger sprayers, such as a stainless-steel tank.

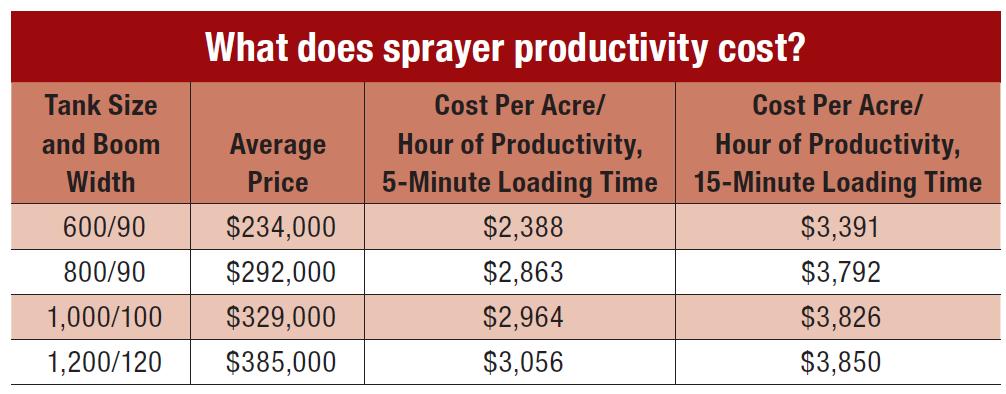

Prices were collected for sprayers of four different sizes. The 600- and 800-gallon sprayers had 90-foot booms, the 1,000-gallon sprayers had 100-foot booms, and the 1,200-gallon sprayers had 120-foot booms. The average price of each class of sprayer and the cost per acre/hour of productivity are listed in the following table.

Several conclusions can be derived from this study:

- Slower loading times increase the cost per acre/hour of productivity dramatically. The increased cost ranges from 26% to 42% higher.

- Spending 10% more for a larger sprayer will increase productivity by about 8%.

- Spending 7% more for an automated mixing system to improve loading times can increase productivity by 20% to 30%.

- It is interesting that the smaller sprayers are more cost effective for their capacities. The manufacturers seem to give a better price advantage to the 600-gallon sprayers — notice the cost per acre/hour of productivity.

The price difference of 100 acres per hour of productivity is shocking when comparing a 1,200-gallon sprayer loading in 15 minutes and an 800-gallon sprayer loading in five minutes. The price of the 1,200-gallon sprayer is 32% higher and costs $93,000 more. Many operations will purchase a large sprayer and not consider loading time efficiencies that cost a fraction of the difference. The lowest-cost means to improve productivity is to reduce loading time.

How efficient is the average sprayer? A major manufacturer aggregated data from the sprayers and found 26% of the engine hours were spent spraying and 28% were spent idling. They calculated a 20% improvement would lower operating costs by $0.80 per acre. A savings of 10 minutes of loading time gives a 20% improvement in productivity.

Based on these numbers, an average 1,200-gallon sprayer is covering about 53 acres per engine hour. We have a customer who averages about 100 acres per engine hour. There is a dramatic difference between the average and an efficient operator and the cost of operation. When it comes time to trade machines, the price is based mainly on the engine hours, not the acres.

In conclusion, the average sprayer has considerable room for improvement. A one-year ROI or less is possible for many operations, and this only considers the engine hours on the sprayer. Additional labor is often needed to prepare the mix to get a fast loading time.

An automated system can do the mixing, loading, and mixing records in five minutes. Stress is lowered on the operator, allowing them to do a better job of operating the sprayer. Accurate measurements and automated records save time in the field and the office.

You have the sprayer. Get the most from it.