Retail Remedies: For Spray Tips and Nozzles, Market Demand Perseveres

Editor’s note: This article is part of CropLife’s new series called Retail Remedies. In Retail Remedies content, we offer solutions and strategies for ag retailers to present to their grower-customers to make dealing with all the uncertainty of the 2022 planting season more manageable. This will include stories on product segments — like the nozzles and spray tips feature below — that can help growers stretch their hard-earned dollars in this time of higher crop input costs.

Editor’s note: This article is part of CropLife’s new series called Retail Remedies. In Retail Remedies content, we offer solutions and strategies for ag retailers to present to their grower-customers to make dealing with all the uncertainty of the 2022 planting season more manageable. This will include stories on product segments — like the nozzles and spray tips feature below — that can help growers stretch their hard-earned dollars in this time of higher crop input costs.

For many sectors that support the agricultural community, the past few years have been extremely challenging. With marketplace disruptions, supply chain issues, and geopolitical uncertainty, many product categories have suffered lost sales/demand as a result.

This hasn’t been the case for the tips and nozzles sector, however. In fact, according to Will Smart, Owner of Greenleaf Technologies, quite the reverse is true.

“We are seeing strong growth again in the nozzle market, after a significant increase last year,” says Smart. “When commodity prices are high, farmers invest in equipment. Even with the higher input costs this year, they are still buying. Most farmers see the nozzle as a critical part of their spraying effectiveness.”

Lucas Olenick, Marketing Manager at Wilger Industries Ltd., couldn’t agree more with this assessment. “The spray tip and nozzle market has continued to be strong in 2021 leading into 2022,” says Olenick. “On the dealer level, with supply chain uncertainty for many products, there is extra emphasis for having healthy stocking orders. At the end-user level, there has been a focus on proper inventory of critical parts like spray nozzles.”

The ‘Drift’ Constant

Still, according to Nick Fleitz, Agronomist at Pentair, there remains two overarching challenges for the 2022 growing season affecting spray tips and nozzles: Achieving effective weed control in the presence of ever-increasing herbicide resistant weed populations and continuing product shortages. “Both issues can make weed control a difficult issue to address in 2022,” says Fleitz. “This spotlights the need to ensure we are applying our herbicides in the most effective manner possible to achieve agronomic efficacy. Pentair Hypro has several nozzles in our product line that provide an effective balance of drift reduction and coverage, that can be utilized to optimize performance of the chemistry being applied as well as the sprayer itself. The Pentair Hypro ULD and GuardianAIR Twin nozzles are two popular nozzles that can provide industry leading spray coverage, while limiting downwind drift potential.”

As Fleitz states, the one aspect of the tips and nozzles marketplace that never seems to change from year-to-year is the quest to minimize off-target drift. “Off-target drift is still a considerable concern in 2022,” says Olenick. “It still maintains being the ‘other half’ of the balancing act between driftable fines and coverage. While off-target drift is something that cannot be avoided completely — even the coarsest nozzles in the world will still produce a very small percentage of driftable fines — there is a greater emphasis on ensuring due diligence when finding a ‘sweet spot’ where spray coverage and efficacy can be maintained, and the drift risk factor is kept at a reasonable level.”

But Olenick adds that there have been some changes in the off-target equation in recent years, particularly as new cropping systems have appeared. “With some newer herbicide regimens, such as dicamba-based platforms, there has been greater differentiation and emphasis on vapor drift,” he says. “Vapor drift being the risk of a chemical evaporating before doing its job; whether through evaporating prior to plant contact or from evaporating after landing on a plant or object. Vapor drift can travel much greater distances with less consistent patterns, as it is dictated by the wind. So, diagnosing, locating, and tracking any drift-damage situation becomes a great deal more difficult and concerning. While vapor drift may often occur and go unnoticed, there are some crops that are extremely susceptible to even a fraction of a percentage of a dose, so there has been greater emphasis on measuring and adjusting spray applications to minimize the chance of damaging vapor drift occurrences.”

Greenleaf’s Smart also points to these newer platforms for some of his company’s recent moves to help customers manage off-target applications. “With input costs at all-time highs, every drop counts,” he says. “Drift is waste. If the product does not hit the target, it is wasted. And, of course, there is the liability of injuring someone else’s property. The continued use of auxin herbicides in-season makes drift control extremely important with these products. This year, Greenleaf Technologies got 11 more nozzles approved for Corteva’s Enlist One and four new nozzles approved for BASF’s Engenia.

“The challenge is to maximize coverage and efficacy while minimizing drift,” he continues. “I believe this is why our DualFan nozzles have become so popular. By hitting the target two to four times in one pass, the DualFan nozzles increase target coverage and product performance. Poor efficacy can lead to resistance. The difference between glyphosate and glufosinate is a perfect example. Before we started to see so much resistance, spraying Roundup was easy. You could spray at low water rates and with just about any nozzle type. With Liberty, coverage is key, but you still don’t want it to drift. Medium to coarse droplets, more water, and multiple trajectories are optimal.”

The Beluga HoseDrop allows for sub-canopy spraying with fungicides and insecticides, getting the nozzles closer to the target.

Another Greenleaf Technologies product that improves coverage and minimizes drift, says Smart, is the company’s newly launched Beluga HoseDrop. “This allows for sub-canopy spraying with fungicides and insecticides, getting the nozzles closer to the target, below the blocking leaf structure, and out of the wind,” he says.

Wilger Developments

Over at Wilger, says Olenick, the company has for many years worked with spot-spraying system manufacturers and partners to ensure proper nozzles are developed and can be used as effective tools when spot-spraying. “Wilger has released two series of narrow-angle spray nozzles for these specific systems, available in 20-, 40-, and 60-degree angles,” he says. “The Combo-Jet DX series of narrow-angle nozzles have been developed for the specific purpose of providing the tailored balance between spray coverage and drift reduction for spot-spraying and other narrow-angle spraying. In addition to the DX series, an ER series of conventional narrow-angle flat fan nozzles have been issued for applications that do not require significant levels of drift-reduction.”

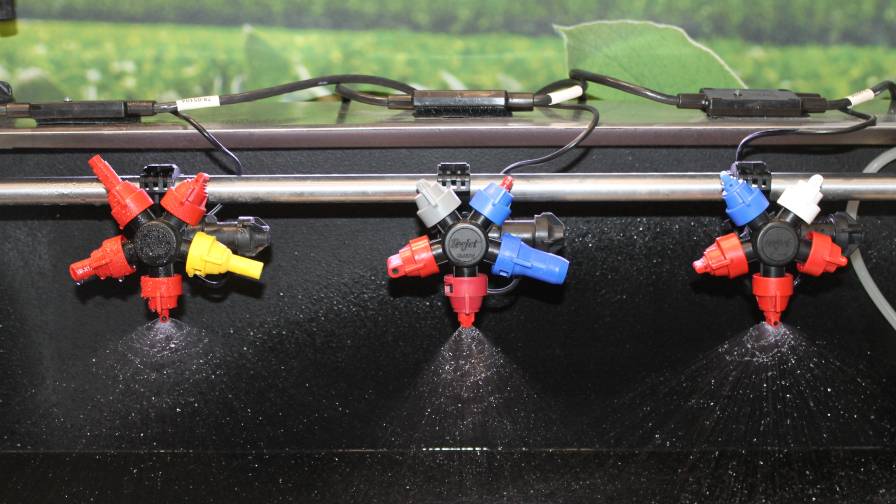

Besides these developments, Wilger has also engaged in the issue of using an angled spray. “In most applications, using an angled spray can compound the issue of inner-crop canopy coverage from the low to mid-range of the plant, so it is less improvement in the sprayer speeds and boom heights that are generally sprayed at in North America,” says Olenick. “So, to combat this, Wilger has developed turrets and adapters to use two tips straight down. Using two nozzles straight down can mitigate drift reduction by having better nozzle options that aren’t too coarse, but still produce a great deal of meaningful droplets for coverage. With the angle still straight down, it alleviates the issue of angled spray tips increasing the distance a spray has to travel before hitting target.”

On the topic of chemical shortages and price increases, Fleitz says that Pentair Hypro is introducing new lines of nozzle control systems in 2022 called Prostop-E individual nozzle control. “There are three product lines within this family, single, dual and quad, that provide varying levels of functionality to the applicator,” he says. “These nozzle control systems can provide chemical savings and limit herbicide carryover through individual nozzle control, more accurate application rates, enhanced coverage and reduced drift potential through the usage of nozzle switching based on ground speed.”

See all Retail Remedies content here.