Tools Expand for Keeping Dicamba on Target in ’21

VRAs, mobile apps, and adjuvants aim to ease volatility and/or physical drift of dicamba.

Last June 3rd, workers at a warehouse in southern Minnesota were busy loading jugs of dicamba onto a truck, destined for Todd Golly’s 6,000-acre corn and soybean farm in Winnebago when the phone rang.

The Ninth Circuit Court in California had, mid-spraying season, handed down its decision to vacate three dicamba registrations.

Todd Golly

“The truck got impounded. That’s how the timing worked for me,” Golly laughs. “I had all these traits and no herbicide to spray on them. It kind of sent us into a panic for a few days until I could get it figured out. That’s when I decided there has to be a more proactive way for growers to mitigate drift damage and try and get ahead of this regulation.”

No stranger to success, Golly had already co-founded the precision farming startup Aker Technologies and scored $2.6 million in private equity funding in 2019 to develop its crop diagnostics and analytics platform. “I’m an agricultural engineer, so I have always liked to use a lot of technology on the farm,” he explains.

The five days it took for the Court to ultimately decide to allow use of existing dicamba stocks may sound insignificant to an outsider, but to the grower and applicator, it could make or break a season.

“I think most farmers are doing a great job — it’s just difficult. We make all these paper maps, we call the neighbors and document what is surrounding our fields, we check the weather apps every day and see which way the wind is blowing, and we try to keep the sprayers going as fast as possible on the right days so we can avoid drift. There are a lot of things to coordinate to do it well,” he says. “That’s when I thought, this would be a whole lot easier if it was digitized and on an app that would do this for you — recommend what fields to spray according to the conditions and the surrounding traits — and so that’s what we did.”

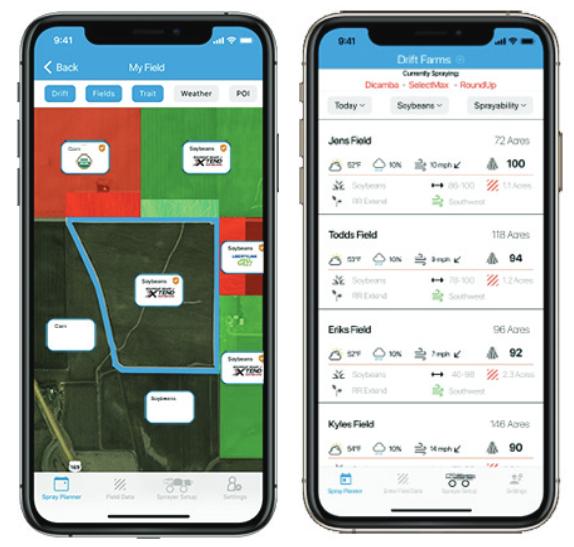

He called friends with whom he had worked on Aker, and DriftApp was born shortly thereafter. The subscription-based ($79/year) iOS app, designed to help applicators put more herbicide on-target, is available to download by searching “Ditch Drift” in Apple’s App Store.

DriftApp auto-generates a Spray Planner based on Sprayability Index, allowing applicators to efficiently keep their sprayers moving while staying aware of potential drift damage. The app replaces the process of managing your seed traits with paper maps, calling your neighbors, and referring to weather apps. Digital maps badged with crop type and seed trait information, easy communication between neighbors, and up-to-date weather conditions are built-in features of the platform.

Moreover, the app offers growers and applicators a chance to see a visual representation of potential drift patterns. “You don’t realize how big that drift pattern really is until you see it on a map,” Golly says, adding that future versions of the app will integrate more features, such as endangered species buffer zones and educational materials.

Golly’s hope is that the app will gain widespread acceptance, so that growers can go all in and start matching compatible beans to plant next to each other. Just one way he is jumpstarting this is by working with ag retailers who are looking to give “drift cards” — a.k.a. gift cards for one-year subscriptions to Drift App Pro to give grower/applicator customers, in lieu of hats or jackets typically given as gifts.

“That would be the best thing: coordination of planting,” he says. “If we want to prevent further regulation and do a good job with this, we all need to adopt these technologies, whether it’s this one or DriftWatch or whatever it may be, and to make sure we follow the labels, because these technologies are just so important for weed control. Weed control is maybe the scariest threat we have in agriculture.”

Drift Expectations for ’21

This year, Golly believes the drift conversation will be no less a factor than in previous years, partly due to compatibility issues: More trait platforms are being used, creating an increasingly complex patchwork, as growers opt for alternatives to the dicamba system.

“Just talking to seed companies around here (in southern Minnesota) we have 25% Enlist, 25% Liberty, 25% dicamba, and 25% Roundup, conventional, or organic. We have a mess of different crop traits that aren’t compatible with each other, so I think spray drift will be the worst it’s ever been, simply because growers don’t know what crop traits to support right now so they plant them all.”

Trait diversity, says Tracy Rowlandson, Technical Market Manager with BASF, underscores the importance of the label specifications: “You are required to look at the sensitive crop registries and survey your surroundings.”

“Having these different trait platforms really highlights the need for communication with your neighbors and to touch base with those who are farming in surrounding the fields to find out what the different trait platforms are, so that you can make proper application decisions,” Rowlandson says.

According to Dr. Tom Mueller, Professor of Weed Science with the University of Tennessee, vapor drift from dicamba will remain a concern, “but hopefully not be the widespread issue it has been in previous years.”

Falling market share of dicamba-tolerant soybeans, rising resistance to pigweed species (waterhemp and palmer), new volatility reducing agents (VRAs), and new cutoff dates that will help reduce applications to large green vegetation and avoid higher temperatures — assuming growers follow the guidelines — are “all factors that will hopefully result in fewer cases of off-target movement in 2021,” he tells CropLife® magazine.

Over the winter, Mueller was granted access by BASF to test its VRA, Sentris for its effectiveness in mitigating dicamba volatility. The results are encouraging as these data suggest that Sentris can decrease dicamba volatilization, in the first 36 hours after application, by about 70% in an Engenia + glyphosate tank mix.

“My data clearly shows that when you add Sentris to Engenia, you get reduced volatility, which is what we are after,” he says, noting that he has other unpublished data that shows that adding Sentris to the spray mixture will aid in subsequent tank and hose cleanouts.

“I believe spray operators, especially custom applicators, will see the need for switching sprayers between dicamba and non-dicamba applications, and spray contamination will be a challenge for those operations when they attempt to move from dicamba to non-auxin platforms,” Mueller says.

Bayer subsequently granted him access to its VRA, VaporGrip Xtra Agent; however, funding for the project has yet to materialize, Mueller notes.

In a blog post detailing Mueller’s findings, his colleague Dr. Larry Steckel writes: “Of all the new label changes on Engenia, adding Sentris to every dicamba application, based on this research, could be the most impactful on keeping the herbicide in the target field.”

VRAs Won’t Stop Physical Drift

Terry Abbott, Adjuvant Branded Project Manager with Wilbur-Ellis, reminds that drift and volatility are separate problems that sometimes get lumped into one.

“That’s where we can get the public confused,” he says. “When the dicamba is moving off target from physical drift (sometimes referred to as particle drift) due to wind, and/or other atmospheric conditions, that is a different problem than volatility. The volatility part of dicamba, where it can lift from the field hours or even days after the spray application has taken place, is what we’re trying to prevent with VRAs.”

VRAs will not prevent physical drift, Rowlandson stresses. Primary off-target movement is addressed by measures like proper nozzle selection, ensuring that your boom height is 24 inches or less above target, applying when wind speed is between 3 mph and 10 mph, and maintaining required downwind buffer distances.

“pH buffering adjuvants are designed to mitigate the impact that happens when you add tank mixes in with Engenia herbicide or other over-the-top dicambas that results in a reduction of the solution pH,” she adds.

When a dicamba solution drops to a pH below 5, it transitions to the acid form and the risk for volatility increases. pH buffering adjuvants, she explains, are essentially products with a neutral to alkaline pH, which keeps dicamba in the anion form.

“What I want to reinforce is that the inclusion of VRAs is not optional or 2021. Every application of Engenia herbicide, has to include a pH buffering adjuvant.” All approved VRAs or pH buffering adjuvants are listed on the Engenia tank mix website. For XtendiMax, visit www.xtendimaxapplicationrequirements.com. For Tavium, visit www.syngenta-us.com/herbicides/tavium-tank-mixes.

For 2021, VRAs are a separate addition to the tank, but next year, all-in-one solutions are expected to make their debut.

Other Key Parts of the Equation

A VRA is now a must in the spray solution, but that does not change the requirement of including an approved drift reduction agent (DRA.)

Issues with physical drift are not expected to diminish anytime soon, as more people move away from the cities and into rural communities, Abbott points out.

In a nutshell, drift reduction, says Abbott, “is very important for Wilbur-Ellis.” The company has steadily expanded its drift reduction technology portfolio to include products like Diligence-EA designed specifically for ground sprays, and for dicamba, Serenity Plus for mitigating water hardness and Serenity Cubed, its all-in-one non-AMS water conditioner, DRA, surfactant, and deposition aid.

Adjuvants that reduce the number of driftable fines that can potentially leave the field minimize an applicator’s liability with respect to spray drift claims, he says.

“In thinking about companies that grow crops that are highly susceptible to herbicides like dicamba, if we can’t manage drift or volatility, it poses a significant danger to their crop and, ultimately, their livelihood. Anybody that plants a crop, at the end of the day, they’re trying to take it to harvest. The last thing they want is to be totally decimated by somebody spraying that wasn’t careful with what they were doing,” he says, adding, “You need to do everything you can to prevent that spray from leaving your field, and that includes a DRA. People are understanding the impacts of it, but I don’t think we’re 100% compliant.”

To that end, he says, education on drift reduction at every step in the value chain is as important as the technologies themselves.

“We as formulators can continue to develop great products, and help minimize the impact of spray drift, but at end of the day, if we don’t train our growers and custom applicators on the value of what these technologies bring them and how to properly apply them, then it’s all for naught,” he tells CropLife. “We need to make sure our growers are getting that message and not only attending the training but understanding it. The last thing you want to do is throw the information out and say, ‘Okay, I gave it to them’ — that’s not good stewardship.”

Whether it be spray drift — what it actually is and what results from it — or what types of products can help them better manage their spray application, “all of it needs to be a focus for us to try to successfully navigate into the future of farming. It’s changed dramatically from 26 years ago when I first got into this business. Back then, nobody talked about drift. But drift has been around ever since there’s been a sprayer.”

Among one of hundreds of new adjuvant products geared toward drift reduction to the market is Attune Agriculture’s Accomplice, an all-in-one adjuvant designed specifically for row crops to manage both drift and improve pesticide performance. Formulated for maximum compatibility across the spectrum of conventional pesticides, Accomplice can provide 51% more weed control than herbicides alone.

EPA approved as a tank-mix partner for use with Enlist One, Engenia, and XtendiMax, Accomplice provides 30% greater drift control than four leading DRAs in aerial applications.

“When you put (Accomplice) in a high-speed, 125- to 145-mph wind tunnel, we separate from the others. Only one or two products are in the same league when it comes to high speed,” says Ed Quattlebaum, Director of Product Development for Attune Agriculture. The data supports its drift control properties, but the product is also in trials for volatility reduction due to its humectant content and the fact that it produces larger droplets.