The Rising Role of Logistics Systems in Ag Retail

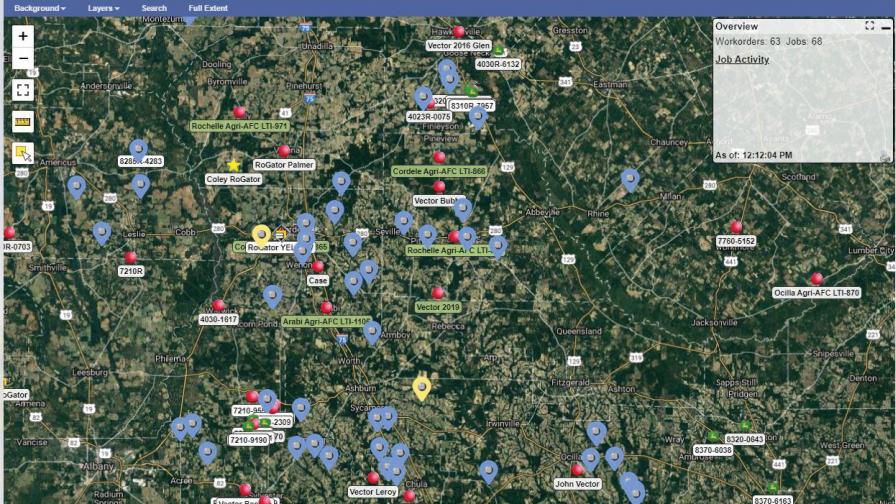

Retailers gain tremendous benefits from virtual maps rendering the locations of tenders and applicators.

Editor’s note: This article originally appeared in December 2019.

Logistical mastery is the bread and butter of any full-service retail operation. For the past decade, with improvements in machine-to-machine communication and mapping technology, retail managers have employed a variety of tools and systems to help ferret out inefficiency.

Through a lot of hard work and trial and error, logistics systems are bearing fruit for retailers who have committed to making them work. This article shares the experiences of three retailers who have successfully added digital logistics programs to their businesses, and some of the key benefits they have realized.

Agri-AFC

Agri-AFC, based in Decatur, AL, has taken a broad approach to its deployment of logistics technology, which has paid dividends in improving machinery efficiency and reducing cost. (Editor’s note: Agri-AFC has merged with GreenPoint AG and Tennessee Farmers Cooperative in September 2020).

Daniel Mullenix, Agri-AFC

Daniel Mullenix, Ag Technologies Manager of the Georgia district, says AccuField is Agri-AFC’s cloud-based precision ag platform backed by EFC Systems. Agri-AFC’s entire fleet of application rigs and tenders carry fleet trackers and telemetry packages that allow all machinery activity to be recorded as well as monitored through AccuField. Retail location personnel use AccuField to manage asset logistics for their location.

The application and tender fleet is a mix of manufacturers, including John Deere, AGCO, RBR, Case IH, and Hays-LTI. API integrations are critical to fleet communication. Examples of API integrations with AccuField include My John Deere, Raven’s SlingShot, and FleetTrax platforms.

In the heat of the application season, tracking tender movement is particularly key to product movement efficiency, says Mullenix. One feature that he would like to see used more is geofencing, which allows a virtual boundary to be set around a specific location, like a fertilizer plant. “So if a tender crossed a geofence placed 5 miles outside the plant, an alert would be sent and the facility would know to start blending the next load before the tender arrives.”

Outfitting every rig with a tracking device is not an inexpensive proposition, but Mullenix has been able to consolidate the company’s cell contracts by working with a third-party data provider. “It allows us to maintain a couple of master accounts and add lines as needed at a deeply discounted rate,” says Mullenix. “They understand agriculture and the systems we use, and it makes it easy and seamless to make changes.”

One unfortunate change that won’t be so seamless is Verizon’s sunsetting of 3G service at year’s end, which amounts to turning a portion of Agri-AFC’s fleet trackers “from assets to paperweights,” says Mullenix. They are working with their equipment partners to upgrade the trackers to 4G for the season ahead.

From a maintenance and replacement standpoint, Agri-AFC plans to use collected data to make better decisions about evaluating and trading in fertilizer equipment. “We’re getting a better idea of spreader life expectancy based on hours of operation,” says Mullenix. “Given what fertilizer can do to a steel spreader, we’re finding that as machine hours increase, so does annual maintenance. We’re looking back at what has traditionally been repair and maintenance fees against the hours we are accruing on a yearly basis, and plan to determine when it makes sense to trade machines for something new.”

Wabash Valley Service

Including the initial pilot test, Wabash Valley Service has been working with John Deere’s AgLogic system for logistics for more than seven years. Over time, the co-op has settled into a logistical approach that’s proven effective for its business.

Travis Correll, Wabash Valley Service

“We went through some trial and error,” says Travis Correll, Technology Manager. “In the beginning we had three different areas of the company split out, with a logistics manager for each area who managed all the spraying, dry fertilizer, and ammonia orders that came through. The logistics manager for that area made the route for each rig each day in the most efficient order.”

Wabash has moved away from that and toward localized plants handling logistics, with managers assigned to cover more manageable regions. Using AgLogic, each of the logistics managers can view their particular region on a digital map, as well as the activities of the other regions.

There are a number of reasons totally centralized logistics didn’t work for Wabash. First is the growing complexity of weed control programs, including the wide variety of seed-herbicide systems and input “cocktails” that must be managed. Second, not every plant keeps a consistent stock of every chemistry, creating an added layer of logistics to manage. Finally, personnel is more often than not inconsistent as far as the number of available drivers at each location.

Wabash uses AgVance to produce the order tickets, and that information flows through AgLogic to an applicator via tablet computer. The company worked with Deere to get the system to work with an iPad, Wabash’s tablet of choice, so field applicators could work on a single platform.

In the future, Correll would like to have more data automatically recorded and not have to rely so much on the applicator to enter information.

MFA Inc.

For the past few years, MFA Inc., Columbia, MO, has been working toward a longer-term plan for overall operational efficiency. A key aspect of the plan will be creating better field operations efficiency, from work order logistics to execution.

Thad Becker, MFA

Due diligence through this past summer led MFA to launch a pilot program across 11 locations using Raven’s AgSync system. MFA currently uses Proagrica’s Sirrus program to build the agronomic recommendation, and the addition of AgSync should allow for a seamless transfer of information and more control of the flow of information by the location manager, says Thad Becker, Precision Agronomy Manager.

“The work orders created in AgSync would live there to allow a manager to organize and release them to applicators when ready,” he explains. “This will allow one person to concentrate on making the right decisions about what to spray in which locations on a given day.”

One of the biggest challenges that has emerged in recent years has been effectively managing the ranges of herbicide systems, including Xtend, LibertyLink, and various combinations, in an efficient manner. With so much riding on accuracy, being able to identify and sort orders can have a huge impact on field efficiency.

On the back end, AgSync will also allow a cleaner connection to the business management software package — MFA uses Merchant from EFC Systems.

As far as expected payback in efficiency from this pilot program, Becker doesn’t have a specific number or percentage in mind. “Ultimately what I want to hear from our people is that it was relatively trouble free, and that they can’t imagine going back to doing things on paper,” he says.