Sackett-Waconia Celebrates 125th Anniversary With an Eye On the Future

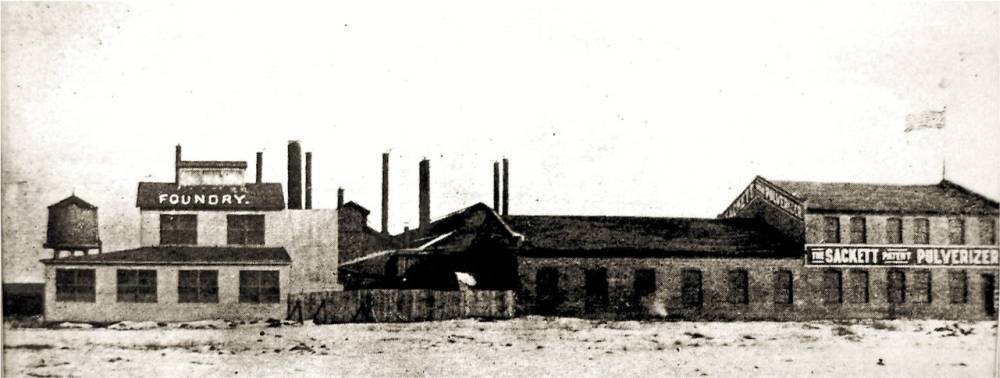

Sackett-Waconia was founded in 1897 as The A.J. Sackett & Sons Company.

Sackett-Waconia, the U.S.-based designer and manufacturer of fertilizer equipment systems, celebrated its 125th anniversary in 2022. The company was founded in 1897 as The A.J. Sackett & Sons company, acquiring a controlling interest in Waconia Mfg. Inc. in 1994.

In 2006, Sackett do Brasil was formed with a Brazilian company to serve Brazil’s fertilizer industry. In 2016, the companies came together under the banner Sackett-Waconia and have continued their mission of providing high-quality design engineering, fabrication, and customer support to the fertilizer industry.

Sackett-Waconia is headquartered in Baltimore, MD, and has locations in North Carolina, Minnesota, and Brazil.

In addition to Brazil, the company operates four facilities in the U.S., including Maryland, North Carolina, and two in Minnesota.

Over the company’s history much has changed, noted CEO Larry Taylor.

“We have seen an evolution over these many years from the early days of crushing and mixing organic fertilizers to the development of high analysis granular fertilizers,” he said.

“Modern agriculture has taken recent advancements a step further to a soil specific model, where accurate blends of high analysis macro and micro fertilizers, soil amendments, and biologicals are required to maximize plant and soil health and improve Nutrient Use Efficiency on every acre.”

When the company was founded in the late 1800s, organic fertilizers were the only ones available, which explains Sackett-Waconia’s location on the East Coast.

Taylor is often asked why the company is headquartered in Baltimore instead of somewhere in the Midwest. It all comes down to shells — specifically, oyster shells.

The company got its start in developing and patenting a mill for crushing oyster shells, which were blended into organic fertilizers.

“We were weighing ingredients, blending them together, bagging them, then shipping them to farmers wherever they were located,” said Taylor. “And because most of the ingredients came in by ship or originated on the water, that’s why we’re here.”

The Leading Edge in Innovation

Sackett-Waconia’s constant innovation is reflected in the number of patents it holds, which currently numbers more than 200.

The company’s sole focus on fertilizer is a defining characteristic in the marketplace.

“One of the really interesting things about our company is that we started in the fertilizer industry 125 years ago, and 100% of our business was in the fertilizer industry then and 100% of our business remains in the fertilizer industry today,” said Taylor.

“While we’ve stretched out our arms in terms of serving the global industry, our focus continues to be on the equipment for the production, handling, and blending of fertilizer, and that’s a unique feature about our company.”

Sackett-Waconia’s longstanding and prominent role in the fertilizer industry was particularly influential when the U.S. government started making sizeable investments in the fertilizer industry after World War II, which included the creation of the National Fertilizer Development Center under the Tennessee Valley Authority and the development of granular high analysis NPK fertilizers.

In the early 2000s, the company experienced another growth spurt as the industry concentrated on bigger blending plants, logistics, and finding more efficient ways to get fertilizer to retailers and farmers.

During this growth period, Sackett-Waconia realized that the industry needed very precise blending systems that offered a lot of flexibility.

“We started to see a lot of new products coming to the market beyond just NPK. For example, more micronutrients, more trace elements, and of course, the concept of Precision Fertilizer Blending [a term and process copyrighted by Sackett-Waconia],” said Taylor.

Indeed, when Taylor started speaking on the international circuit about 35 years ago, the consensus at that time, especially outside of the U.S., was that blending would not work because it wasn’t accurate enough.

Ultimately, that premise was disproved. Taylor estimates that 50% of the multi-nutrient fertilizers distributed today are blends.

According to the company, agronomy, planting, and spreading of fertilizer have all seen large technological leaps over the last decade. Blending is a main link between fertilizer production and nutrient uptake, and it’s also the last link in the chain that needed improvement.

Sackett-Waconia’s Precision Fertilizer Blending technology assures that blended multi-nutrient fertilizers meet the analysis determined by soil- and crop-specific requirements to maximize yields, minimize environmental impact, improve human and animal nutrition, and ensure farmers’ economic success.

Simply put, even the best nutrients and application technology cannot maximize nutrient use efficiency without highly effective blending, and Precision Fertilizer Blending ensures farmers can put down the right source, at the right rate, at the right time.

Keeping Pace with Industry Trends

There are other notable trends impacting the fertilizer industry, said Taylor.

He recalled a conversation with a customer a few years ago. When asked about the biggest concern he had for his business, the customer responded with “traceability.”

The customer explained that food companies were increasingly requiring more accurate information about what was in the food, how it was produced, and that everything was verifiable and traceable, and this was something that the fertilizer industry needed to respond to and support.

Automation is another trend, said Taylor.

“Ten years ago, 90% of the plants we sold were just equipment. There wasn’t automation. However, today we don’t sell a plant without automation.”

Looking into the future there will continue to be new products, some of which may need to be applied in ounces or pounds rather than tons, due to the ongoing quest to improve nutrient use efficiency.

“Everything comes back to this,” remarked Taylor.

Ideally, the goal is 100% nutrient use efficiency by the plant with nothing going into the air or water.

The current challenges and opportunities in the fertilizer industry are exciting, said Taylor. These range from improving sustainability to increasing yields to feeding a growing population, which all need to be addressed simultaneously.

Taylor added that while the fertilizer industry may not be a growing industry, it’s certainly a perpetually changing one.

“There’s not going to be a lot more land put into production,” he explained, but the introduction of new products, processes, customer demands and more will spur further evolution in the fertilizer industry.

Sackett-Waconia’s success is built on another key philosophy, emphasized Taylor, and that’s listening to the customer.

“While asking questions is a good thing,” he acknowledged, “listening is even better.”

He recalled a college professor who used to say, “You can’t learn with your mouth open.”

It’s something that Taylor frequently reminds his team to do when they’re out in the field.

“I tell our folks to always make sure you’re hearing what other people are saying instead of telling them what you think you already know,” he said.