How to Set Up Good Systems for Actionable Agronomic Data

By investing the time upfront to employ a good strategy, the data can do its best work and offer several advantages.

In the past, I shared a few tips for applying, what I like to call, “rescue treatments” to bad data, in order to clean it up and make it usable.

But what if data didn’t need to be rescued? What if systems could be set up so growers are collecting good data right from the start?

When it comes to agriculture equipment, we preach preventative maintenance (PM) as a strategy to promote more uptime and protect farm machinery so it can do its best work. Setting up a grower for data success is a similar concept; by investing the time upfront to employ a good strategy, the data can do its best work and offer several advantages.

Here are three PM strategies to employ with growers to help ensure data collection is clean from the start.

Define the Crop Year

It’s quite amazing that something as simple as having the right crop year can have such an impact on a dataset. The question is, when does one crop year end and another begin?

It’s not a simple answer. That question poses a challenge to growers because there’s no one way to define a crop year. There’s no right or wrong answer. It all boils down to a grower’s preference and circumstances.

For example, if a grower plants wheat in the fall, is that for the next year’s crop year? What if the wheat field is kept fallow after harvest and spraying happens later in the fall – what year is that considered?

Fall tillage presents another unique situation. Technically, harvest should be the very last operation of a given crop year, right? But when both combines and field cultivators are running simultaneously, it’s very easy to think of that pass as being part of the same year.

This is typical. And the only real, “right” answer is this: consistency. Consistency is critical when it comes to looking across multiple years of data. However the grower chooses to define crop year, first ensure it makes sense and is repeatable year after year, then establish it as the consistent basis.

Multiple Crop Year

There’s also an option of breaking down a crop year into multiple pieces. Think again about those fall-planted crops or cover crops. It might make sense to say that harvest ends the crop year, but it also might make sense to create a second crop year or an off-season.

Not all data management systems can handle that sort of notation but, for those that do, it can be a big help. For growers who have a lot of double-cropping practices, fallow, or cover crops, it might make sense to seek out a system that supports breaking down a crop year into multiple pieces.

With any crop year strategy, there certainly is the option to let the data flow and sort it out in the end. But to avoid having to take the extra step, or apply a “rescue treatment” establish consistency now.

To best establish good data, start by setting up the boundary.

Why Boundaries Matter

Everyone has boundaries, everyone needs boundaries. Data needs them, too.

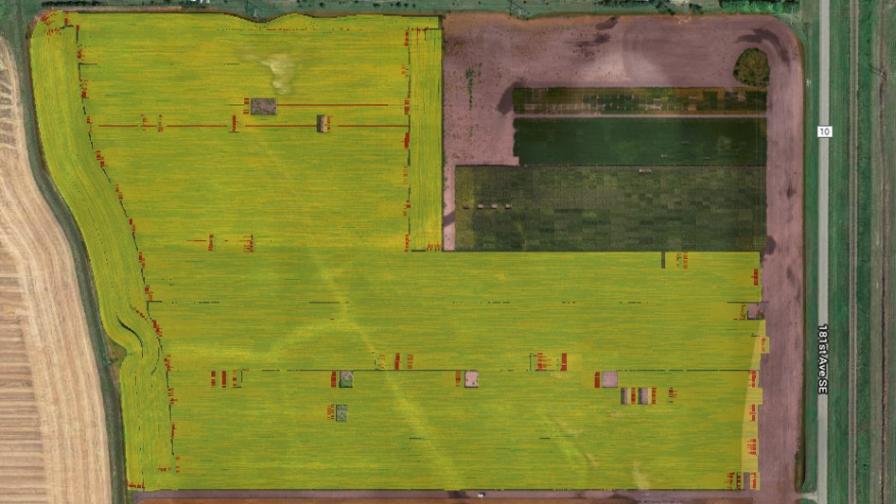

The vast majority of data clean-up issues result from a boundary issue – too big, too small, not the right shape, or simply not existing. To best establish good data, start by setting up the boundary.

It sounds simple but there’s a catch: Growers tend to hate it. When they’re ready to get started, the last thing many want to do is take the time to name every single field. Not only that, it requires some thought as to how to break it out, thinking about how each is farmed, and those types of things.

The process, no matter how you slice it, is time-consuming. It’s boring. It can be frustrating. But it’s crucial. And it’s a time investment that pays back a big return. Think back to the idea of PM. It’s time-consuming. It may be boring or frustrating. But it’s crucial and it’s always worth it.

Setting Up Boundaries

Once a grower comes to terms with the idea of establishing boundaries, it’s time to get to work.

The greatest number of user-facing updates to the John Deere Operations Center are focused on simplifying the boundary creation process. It’s as simple as draw the field, name the field, repeat.

Boundaries can be defined in a number of ways. They can be driven (preferably with RTK to minimize satellite drift). They can be generated by an application map. They can be imported from an FSA boundary shapefile. Or – as a way to get things rolling – they can be manually drawn.

The accuracies of each depend upon the GPS data, the base map layer, or how much time a grower wants to spend clicking around the field. The advantage is they can be manipulated, overwritten with a new file, or simply deleted. So don’t worry about being perfect. Just worry about getting the process started.

On a personal note, I’ve found that having a grower hand-draw all of the boundaries on a printed map helps out a lot. Also, making notations of the field entrance, obstacles that exist, and any discrepancies between the map and what’s really out there. The more info, the better; having the notes in advance of processing field data can help when it comes to interpretation.

Planting, Spraying, and Harvest Data

With the basics set up properly, it’s time to execute the strategy in-season and do so in a way that continues the flow of good data.

Planting and spraying data are relatively new additions to the game, and other than making sure machines are calibrated for their mechanical purpose (such as conducting meter run-offs or calibrating nozzles), there is not much more to be done when it comes to preparing for the operation.

For growers running prescriptions, ensure those are loaded in the display, and all documentation and setup files are properly installed with current information.

Just as consistency is key in defining crop year and naming boundaries, it’s crucial for product names. EPA registration information for pesticides, proper seed naming nomenclature, and correctly labelled tank mix components are all key components that will make application and seeding maps as accurate as possible when it’s time to analyze them later.

Harvest data always seems to get the most attention. After all, the practice of yield data collection has been common since the early 1990s. A few points can be followed to improve the quality of any grower’s harvest data.

First (and there should be no surprise here) is calibrating the mass flow sensor. There are a number of new tools growers have which can help to automate and speed up this task (such as adding a scale to the grain cart, or installing ActiveYield). If this sensor is not calibrating on every crop changeover, expect to have to resort to a “rescue treatment”.

The next two best practices, while directly related to the data coming in, are actually more operating tips than set up. Understand that arming the grower with this type of best-practice advice is a good practice but he or she may choose to ignore or simply forget.

First, make sure header height is set correctly for the crop being harvested. While it might not seem like that big of a deal, imagine a grower last harvested wheat. He or she will more than likely be changing the setting when going to corn and soybeans. However, if going from soybeans to grain sorghum (or another tall, stemmed plant), header probably won’t need to be nearly as low to the ground, which may cause the machine not to document the pass made in the field.

Next is to maintain consistency in making the pass. Lifting the header at the end of the pass to start a new pass log, keeping a consistent speed, and ensuring the header is always “full”.

Having a full header is important because currently a system doesn’t exist to decipher how much of the header is actually taking in grain. All calculations will be based upon the fixed number of recorded header width.

This becomes incredibly important when it comes to the dreaded “row of shame”. Newer combines will actually throw these single pass rows out if an “overlap” is created by completing the pass with the majority of the header being on the side already harvested…and not combining it right down the middle or in sequential order as though the new pass consists of a full header.

Looking Ahead

A good data strategy is like a good PM strategy – invest the time to do it right and it will pay back. And remember, there are some situations where data can’t be rescued. To avoid the headache of dealing with unusable data, set up each grower for success from the start.