Controllers’ Power On The Rise

Trimble FmX TMX-2050 Field-IQ SwitchBoxes

The increasing capabilities of the coming season’s rate controllers couldn’t come at a better time. Indeed, continuing high costs for fertilizer, seed, fuel and labor are forcing applicators to utilize technology to minimize waste, says Colin Pollack, sales specialist — custom application, with Ag Leader Technology. In addition, with concerns over problems such as run-off and algae blooms, legislation is either already in place, or soon will be, requiring all fertilizer applications be recorded, to ensure farmers are using responsible practices.

“The result is a need for a more function-rich rate controller that utilizes GPS position data to geo-reference what was applied, where it was applied, when, and how much was applied,” he says.

Then, too, ever-larger and more sophisticated implements need controllers up for the job. Rate controllers can now be used to handle an increasing number of materials or sections of an implement simultaneously, points out Pat Fuchs, product manager-Farmstead and public works, DICKEY-john.

And perhaps one of the biggest reasons for advancing rate controller use is the development of components from different manufacturers that really do communicate with each other. “ISOBUS integration is something that’s been talked about for a long time, but over the last year and a half, two years, it’s really gained some traction,” says Ryan Molitor, marketing and business development operations manager, Raven Industries.

Now Available

As controller tasks have multiplied, so have the recent product choices on the market.

In August, Raven announced the introduction of its Hawkeye nozzle control system, and the company started shipping this month. The system utilizes pressure-based nozzle control, in contrast to previous flow-based technologies. Molitor says the approach reduces spray drift and produces accurate droplet sizes even as drivers speed up or slow down through a field. And it allows users to maintain a consistent pressure across the entire width of the boom.

“For the guys who are operating a self-propelled machine, with booms reaching 100, 120 and 132 feet long, the Hawkeye enables them to deliver a consistent spray pattern across the entire boom at a wide range of speeds,” Molitor says. The system also provides turn compensation, again, allowing a consistent pattern across the boom.

Molitor says Raven leads with the fact that that Hawkeye is an ISO-compatible controller. Many customers already have an ISO-compatible display terminal in the cab — and they’re not always interested in switching that out — maybe want to add control of some other vital functions of the machine. That’s why it’s important to them to have that capability, he says.

Raven will be offering machine-specific kits for users to purchase to outfit their favored-brand application rig. Initial kits started shipping in November, with additional options coming through December and January for the most popular machines on the market, says Molitor.

Ag Leader offers the DirectCommand application rate control solution with approximately 80 machine specific kits to afford the user with functionality across a huge selection of application equipment, Pollock says. “When used in conjunction with Ag Leader’s Integra or Versa displays, these easy to install and use DirectCommand kits offer complete control over liquid and granular application of products,” he says. In November, Ag Leader began offering new software enhancements for users. Customers can expect to see more improvements in granular application using spinner/spreaders.

In another show of brand flexibility, TeeJet Technologies’ new DynaJet Flex 7120 sprayer control is designed to piggyback on to existing rate control systems. The system utilizes PWM (pulse width modulation) technology to control flow rate independently of operating pressure. It allows operators to select target droplet size on the go, from the cab, and maintain that droplet size across a wider range of ground speeds and/or application rates.

The DynaJet system can be paired with TeeJet’s new Aeros 9040 Field Computer — a full featured field computer (ISOBUS UT compatible) that provides GPS guidance and rate control in one package, says Tim Stuenkel, global marketing communications manager.

Topcon’s new CAN-based/ISO-compatible Apollo CM-40 has the ability to control four independent control loops with 10 outputs. When paired with the Apollo EM 24 as the Expansion module, it can accept 40 input lines and 24 output lines to enable control of more sophisticated implements as they continue to become both larger and multi-function, explains Michael Gomes, vice president of business development.

Apollo ECUs also offer the flexibility for customers to upgrade and utilize them with Topcon’s X25 or X30 displays to import prescription maps and generate real-time as-applied maps and more advanced functionality. Operators have the ability to simultaneously control and record data for up to eight products with the X30 console.

The Trimble Field-IQ crop input control system enables productive and efficient functionality for planting, nutrient and pest management operations. “Users save on input costs by monitoring and simultaneously varying up to six different materials to precisely plant seeds, apply chemicals and broadcast fertilizers,” says T.J. Schulte, smart machines market manager for Trimble’s Agriculture Division. Users can adjust seed population, fertilizer rates or spray application manually or use a prescription from FarmWorks Mapping software.

Buyers Differ

The rate controller market has shown flexibility, adapting to varied levels of customers’ needs and precision ag expertise. In May, AGCO introduced its new AgControl rate controller, available only on the RG700 model. “It’s a controller with a main focus of product control instead of a field computer,” says Craig Miller, sales and marketing specialist. He points out that the market has developed to offer multiple levels of rate control systems. “I think we all have our field computer versions — your top of the line, best product with the best features. Then there generally seems to be a second, more cost effective option that’s not going to have nearly as many features in the console.”

The IntelliAg AI series system is DICKEY-john’s high-end control system, providing four channels of application control, variable-rate application, section control and recording as-applied material in the field. Designed around the ISO standard, the controller can be used in a wide range of applications including on planters, grain drills, air seeders, liquid sprayers, granular spreaders and anhydrous ammonia units.

But DICKEY-john released a new product in February, the IntelliAg MVT series system to meet the needs of different users. The MVT utilizes the IntelliAg AI series baseline but is designed to be a simpler system at a significantly lower price point for growers who only require planter population control with seed monitoring and liquid or granular fertilizer application without the complication of GPS technologies, explains Fuchs. The MVT simply controls the application of seed, liquids and fertilizer based on the ground speed of the tractor — it is not dependent upon the variable-rate prescriptions and section control. Users just turn the system on and start planting the field.

AgJunction’s Outback MAX was designed to receive increased functionality and compatibility over time, broadening its application and appeal to an ever wider customer base. Last spring AgJunction released its Advanced Task Controller for ISOBUS — and last fall the company added its Virtual Terminal feature for Outback MAX to support ISOBUS implement control. This latest Advanced Task Controller release complements that functionality by now supporting automatic section control and rate control for compatible ISOBUS-ready implements such as planters and seeders.

This fall, Raven’s Viper 4 field computer in itself became an ISO virtual terminal with task controller capabilities. “We’re taking our field computer and making it ISO-compatible so that other stuff can plug into it as well,” explains Molitor.

No matter what level of system, AGCO’s Miller offers a simple suggestion: Read the manual. “Consoles can do so much more than I think most customers realize,” he explains. And they’re only going to become even smarter and more advanced. The manual is going to be the key for a user to really to understand what can he truly do with the system in terms of data transfer and in terms of big data that he can get out of the machine and out of the system.”

Doing More

Implement manufacturers continue to release more options that allow rate controllers to maximize efficiency.

“They’ll continue to push the limits of both multi-product control and increasing sophistication with ability to interface with sensors for improvements to the feedback and control, all while creating the as applied records for what was done where,” says Topcon’s Gomes.

Variable-rate application will start utilizing smaller grids of rate zones, enabling more precise application of seed and fertilizer, says DICKEY-john’s Fuchs. “The trade-off here is that more soil testing will likely be necessary to create sufficient data to utilize these smaller grids. We also see the need to control additional materials simultaneously, for example the ability to control the application rate of eight materials at a time vs. four today.”

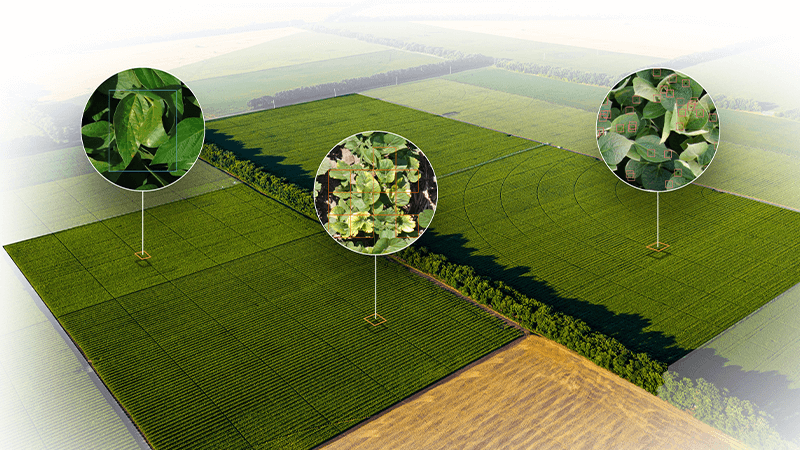

Trimble’s Schulte would say it’s not so much about using a rate controller any more as it is about utilizing variable-rate application of an array of inputs. Soil type, water retention, seed varieties, weather, vehicle speed, crop health measurements — these are a few examples of the data points a grower can combine to make intelligent decisions.

The Trimble Soil Information System (SIS) solution along with the Trimble Irrigate-IQ solution can be used together to create a variable-rate irrigation schedule across different soil types in a single field, while Trimble’s GreenSeeker system and PurePixel solution are two separate avenues for growers to measure plant health and then work with their advisors to prescribe fertilizer applications.

AGCO’s Miller believes the rate controller market will continue to be affected by changing user expectations from technology. One example: Customers are demanding the functionality of the touchscreen user interface now available on tablets and smartphones.

“It’s about screens that you can swipe back and forth — and consoles with different icons and screens in different locations depending on how the user wants to see it,” Miller says. “I think the demand is consoles become much smarter than what they have in the past and much more customizable.”