Yargus Meets Material Handling Needs Of CHS Primeland

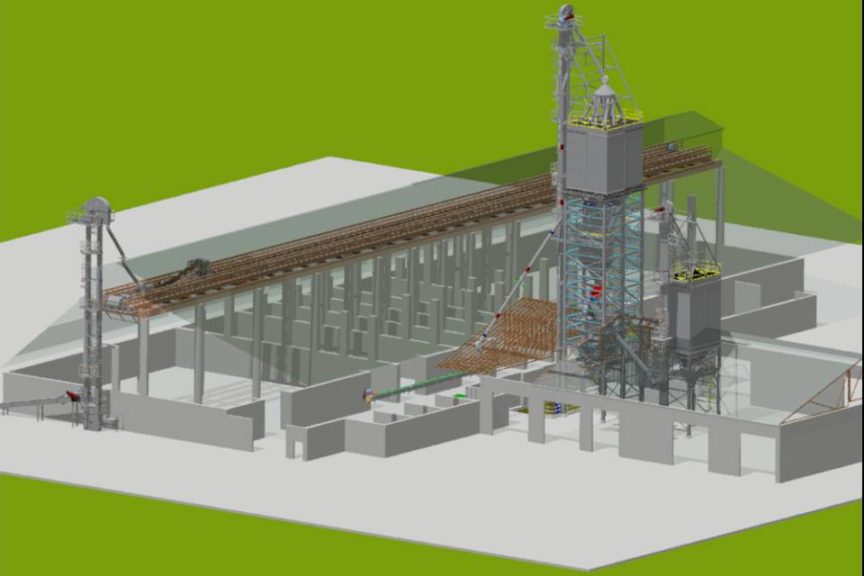

When planning its new Agronomy Hub Plant in Clarkston, WA, CHS Primeland partnered with Yargus Manufacturing for its material handling needs.

Design & Customization

Yargus Manufacturing designed, manufactured and assembled Port of Wilma Agronomy Hub Plant’s fertilizer receiving and blending equipment with the goal of increased speed and capacity for closer product storage and better logistics. According to Ken Mingo, Seed and Agronomy Division Manager of CHS Primeland, “When we were in the planning stages of our new Agronomy Hub Plant in Clarkston, WA, we invited several suppliers to give us their product line to see which was going to be best for our needs. Yargus Manufacturing provided the best solution for us in their Layco line. A twin blender 250 ton dry tower along with a 150 ton liquid tower for melting fit our needs perfectly! We are very happy with the level of customer service and interaction that Yargus provided throughout the construction of our facility.”

The dual 400 TPH Rail and Truck Receiving System moves product through the Industrial Bucket Elevator Leg with a high capacity Tripper Conveyor to distribute fertilizer into each storage bin. The In-Floor Conditioning Hopper with a good-product bypass prevents product degradation. This conditioning system facilitates fast and efficient charging of the 300 TPH Blend Tower. A similar unit for urea enables CHS Primeland to customize their proprietary liquid fertilizer blend.