Stueve Construction Increases Efficiency for Three Ag Cooperatives

A leader in constructing dry fertilizer storage and chemical warehouse solutions, Stueve Construction helped three co-ops — Countryside Cooperative, Frontier Cooperative, and NEW Cooperative — continue to better serve their customers with speed and accuracy.

Countryside Cooperative, Durand, WI

WHAT THEY NEEDED

Durand Cooperative and Mondovi Co-op Equity Assn. consolidated on September 1, 1998, to form a new cooperative named “Countryside Cooperative.” Countryside Cooperative is the west-central Wisconsin’s premier member-owned cooperative, dedicated to service and committed to success, governed by integrity, and driven by a passion of excellence towards a future without boundaries!” says Frank Brenner (CEO/General Manager). “Our business is changing in this fast pace world and our goal was to put together an Agronomy Center Complex that was able to better serve our clients, was centralized, efficient, expandable for the future and cost effective,” says Mike Christenson, Agronomy Division Supervisor. “We looked at several builders in our exploratory stages, but after several tours and doing our due diligence we selected Stueve.

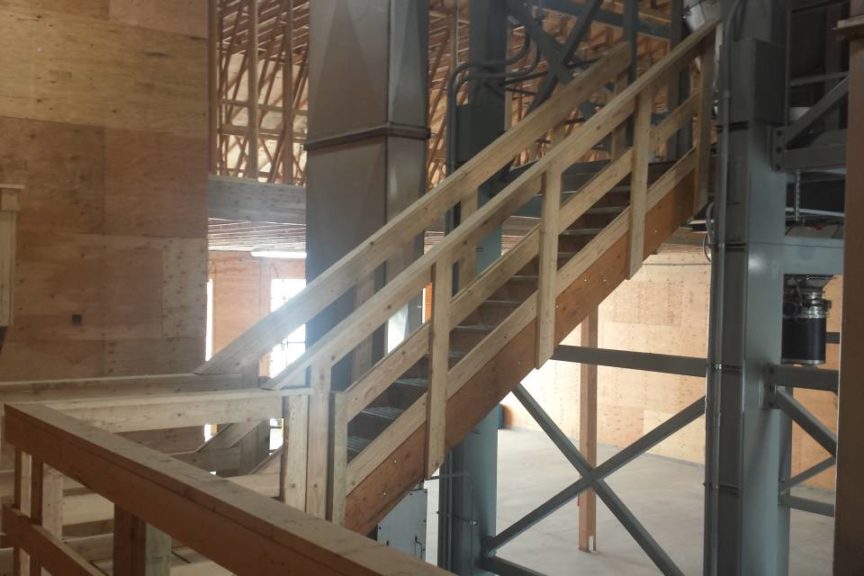

Their experience and ‘in-house’ engineering was the difference in looking at the rest of the field. As a result we now have an Agronomy Center Complex that can handle our dry & liquid fertilizer storage needs and bulk & package chemical needs all in one facility. We really like the elevated control room layout, access to the blend tower platform, natural light effect in the catwalk & bin area, and enclosed truck receiving. The building Stueve has built more than exceeded our expectations at the end of construction!”

WHAT WE DESIGNED

“Mike Christenson, Agronomy Division Supervisor with Countryside Coop, reached out to us early in their planning process,” said Steve Anderson, Vice-President of Sales & Marketing. “Mike had an excellent vision on how he would like to see how his Agronomy Center Complex laid out. We toured several facilities with Mike, his agronomy team and Board of Directors. It was the CEA@Ocheyedan, IA. Facility that was very appealing to all. It had a lot of the same features that Countryside was looking for in their project. Teaming up with Sackett/Waconia, Kahler Automation, and RC Peterson Electric were key components in making the project work well and successful for our client.”

Frontier Cooperative, Schuyler, NE

WHAT THEY NEEDED

Frontier Cooperative has been proudly serving customers since 1915 in eastern Nebraska. “We continue to invest in facilities, resources, equipment, and technology to ensure that our products and services are able to meet the ever-changing demands of the producer and consumer,” said Randy Robeson (CEO). Frontier Coop has established structure and core set of values that are instilled in each of its departments. “Our dedication and commitment to those core values ensure that our patrons receive their products and services they require in an efficient and cost-effective manner,” relates Jon Brabec, Marketing Manager. “Our team toured many facilities across the Midwest to look at building layouts and equipment. We have an established and trusted relationship with Stueve Construction as a result of a recent facility that Stueve built for us in Mead, NE.”

“Their experience, in-house engineering, and quality work is second to none in our opinion,” said Levi Durnal, Agronomy Operations Manager.

“From planning stages to final product Stueve has delivered one of the most efficient ‘state-of-the-art’ building solutions that could ever be imagined. It’s all about the details and Stueve has delivered!” said Caleb Kort, Schuyler Agronomy Hub Manager.

WHAT WE DESIGNED

“Randy Robeson, Levi Durnal, and Jon Brabec reached out to us early in the project and wanted to put together a game plan for a ‘Hub Plant Building Solution’ that could handle unit train shipments and on the outbound side move product quickly to their clients,” describes Steve Anderson, Stueve Construction, Vice-President of Sales & Marketing. “In working with Yargus and Kahler on the project a ‘state-of-the-art’ laser system was implemented at the Tripper Conveyor to add to their precision. They also wanted to be able to efficiently use ‘enhancer products’ (impregnation) in their blending capability as well.

“Frontier Cooperative’s team did their homework and had a great vision on how they would like to see their building come together for today as well as for tomorrow. Expandability was definitely in the mindset for future phases as their business changes.”

NEW Cooperative, Roelyn, IA

WHAT THEY NEEDED

NEW Cooperative, Inc., with 36 locations in North Central and West Central Iowa, has seen tremendous growth and change in their customer’s needs since 1973. “Our mission is to add value to our members’ farming operations. Our vision is to be an innovative and efficient provider of today’s Ag markets and services,” says Dan Dix, General Manager. “The first phase of our Roelyn location was the construction of an 8,000-ton hub plant in 1995. The second phase we did a 12,000-ton addition to our original building that was completed in 2004. Continued business growth led to our recent expansion, the construction of a 50,000-ton facility that we completed in 2016. This tied the entire Roelyn complex together.”

Frank Huseman, Operations Manager, stated: “We wanted to continue to develop our entire Roelyn site to increase our operational efficiencies for our customers with regards to their dry and liquid fertilizer and ag chemical needs.” “It’s all about speed and accuracy when serving our customers,” describes Rod Brant, Region 3 Manager. “Stueve Construction has been a major part of our growth by constructing multiple facilities for us across our trade territory over the years. We really value their experience, vision, in-house engineering, innovation, and excellent communication of the trades during construction.” “In addition, we appreciated their great service and assistance in developing a fantastic site plan at Roelyn,” added Huseman.